first multi-story 3d home in Australia built in 5 months

first multi-story 3d home in Australia built in 5 months

In a quiet suburb of Melbourne, a revolution in housing is taking shape. A landmark achievement has been reached with the completion of the first multi-story 3d printed home in Australia. This two-story, three-bedroom dwelling was constructed from foundation to finish in just under five months, signaling a potential paradigm shift for the nation’s building industry. The project, led by innovative construction firm Fortify+, is more than just a house; it’s a proof of concept that could help address issues of housing affordability, sustainability, and construction speed.

For years, 3D printing in construction was limited to single-story structures or experimental components. This project shatters that ceiling, demonstrating that additive manufacturing is ready for mainstream, complex residential applications. As Australia grapples with a housing crisis, this technological leap couldn’t have come at a better time.

A New Construction Milestone for Australia

The completion of this home in Wallan, Victoria, marks a pivotal moment. Traditional construction for a home of similar size can often take 12 to 18 months, plagued by weather delays, supply chain issues, and labor shortages. The Fortify+ team managed to erect the structural walls of both stories in an astonishing 200 hours of printing time. The remaining months were dedicated to roofing, plumbing, electrical wiring, and interior finishing—tasks that were integrated seamlessly with the 3D-printed structure.

This project isn’t just about speed. It represents a significant step towards automating parts of the construction process, a field that has been notoriously slow to adopt new technologies. By using a robotic gantry system to print the home, Fortify+ has created a blueprint for a future where homes can be built faster, with greater design flexibility and potentially at a lower cost. This achievement places Australia on the global map of advanced construction technology, alongside pioneers in Europe and the United States.

The Technology Behind the first multi-story 3d Build

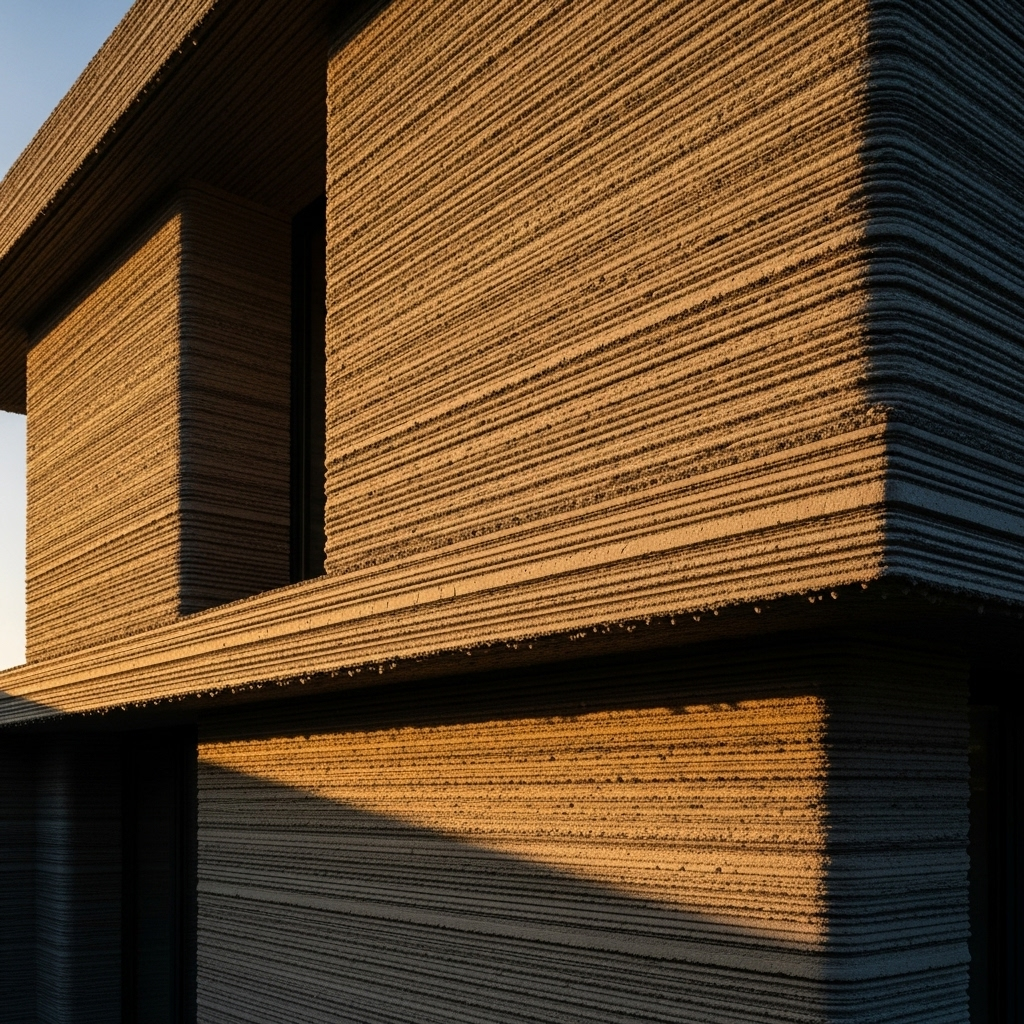

So, how exactly do you print a two-story house? The process behind the first multi-story 3d home is a marvel of modern engineering. Fortify+ utilized a large-scale gantry printer, a massive, rail-mounted robotic arm that extrudes a specialized concrete mixture layer by layer. Think of it as a giant, high-tech pastry bag building a house from the ground up.

The material itself is a proprietary, fast-setting concrete blend. It’s engineered to be fluid enough to be extruded smoothly but strong enough to bear the load of the subsequent layers almost immediately. This allows for continuous printing, a key factor in the project’s rapid pace. The printer follows a digital blueprint (a CAD model), laying down the material with millimeter precision to form the interior and exterior walls. Cavities are intentionally left within the walls for insulation, plumbing, and electrical conduits, which are installed later.

Achieving a second story required careful structural planning. Steel reinforcements were integrated into the printed walls at key intervals, and a pre-fabricated concrete slab was lowered into place to form the base of the second floor. The printer was then raised to continue its work on the upper level. This hybrid approach—combining 3D printing with some conventional methods—is crucial for meeting Australia’s stringent building codes and ensuring long-term structural integrity.

The Three S’s: Speed, Sustainability, and Savings

The benefits of this construction method can be summarized in three key areas: speed, sustainability, and savings.

Speed: As demonstrated by the five-month build time, the most immediate advantage is the dramatic reduction in construction timelines. The automated printing process runs continuously, unaffected by many of the typical delays that plague traditional building sites. This means families can move into their new homes sooner, and developers can increase their output.

Sustainability: 3D printing is an inherently less wasteful process. The printer only deposits material where it’s needed, reducing construction waste by up to 60% compared to traditional timber-frame or brick-and-mortar methods. Furthermore, the concrete mix can incorporate recycled materials, further enhancing the home’s green credentials. This reduction in waste and optimized material use significantly lowers the project’s overall carbon footprint.

Savings: While the initial investment in the technology is high, the long-term potential for cost savings is immense. Reduced labor costs, minimal material waste, and shorter construction timelines all contribute to a lower final price tag. As the technology becomes more widespread, experts predict that 3D-printed homes could become a key solution for providing affordable housing across the country. Fortify+ estimates a potential 20-30% cost reduction compared to equivalent traditional builds once the technology is scaled.

Overcoming Hurdles and the Future of Aussie Homes

The journey to completing Australia’s first multi-story 3D home was not without its challenges. The primary hurdle was regulatory. The team worked closely with local councils and building authorities to ensure every aspect of the project met or exceeded the National Construction Code (NCC). This required extensive testing and documentation to prove the safety and durability of the new materials and methods, setting a vital precedent for future projects.

Public perception is another factor. Some may be skeptical about living in a “printed” house. However, the finished product is indistinguishable from a high-end modern home, featuring smooth interior walls and a textured, architecturally interesting exterior. As more projects like this are completed, consumer confidence is expected to grow rapidly.

Looking ahead, the future is bright. The success of this project paves the way for further innovation. We could soon see entire communities of 3D-printed homes, designed for resilience against bushfires and extreme weather. The technology also allows for incredible design freedom, enabling architects to create curved walls and unique forms that are difficult and expensive to achieve with traditional methods. With backing from research institutions and government bodies, as detailed by leading technology firms like COBOD International, this technology is poised to move from a novelty to a cornerstone of the Australian construction industry.

In conclusion, the completion of this first multi-story 3D printed home is far more than an engineering feat. It is a bold statement about the future of living in Australia—a future that promises to be faster, more sustainable, and more accessible for everyone.

“`