just 5 months: Australia’s 1st 3D Printed Home is Here

just 5 months: Australia’s 1st 3D Printed Home is Here

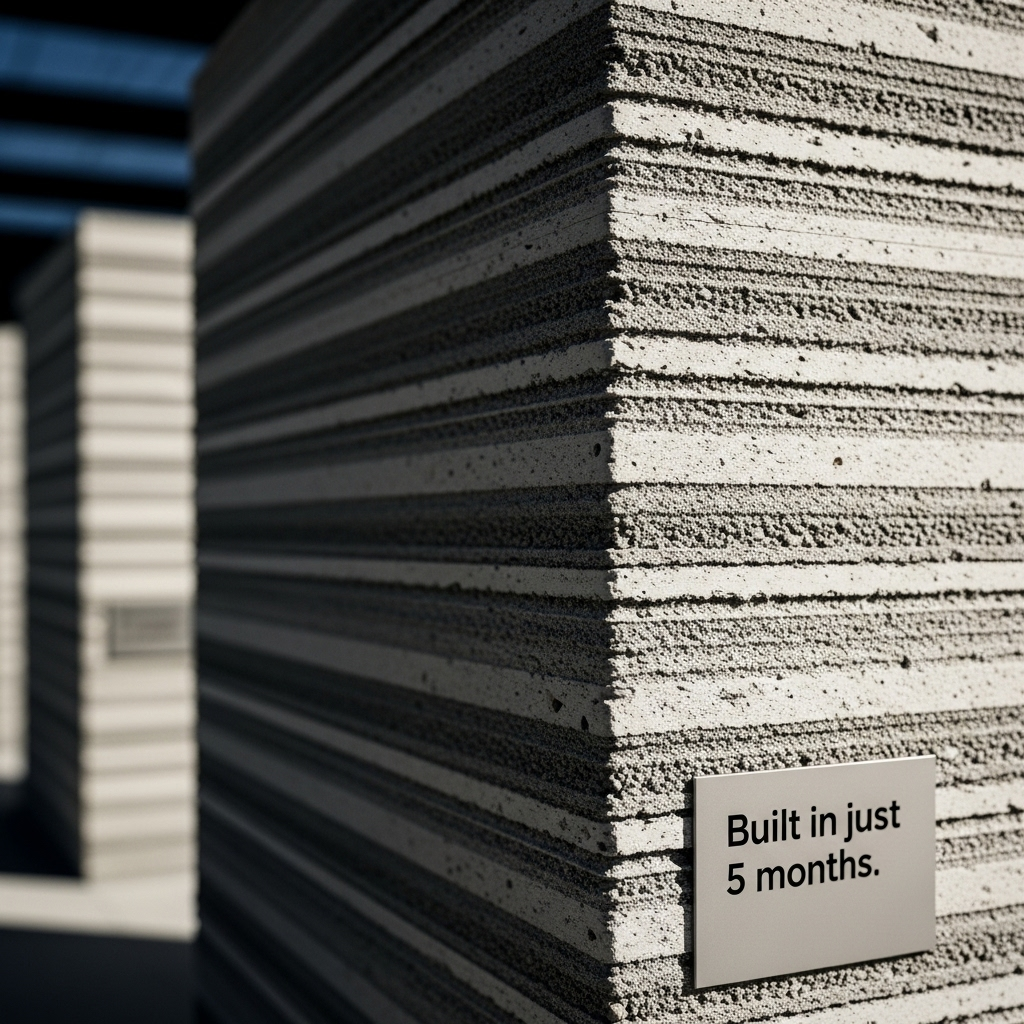

In what can only be described as a construction revolution, Australia’s first fully functional, council-approved 3D printed home has been completed in Melbourne. The most staggering part? The entire process, from foundation to finishing touches, took just 5 months. This groundbreaking achievement signals a monumental shift for the nation’s construction industry and offers a tangible glimmer of hope for its housing affordability crisis.

Forget the traditional timelines that stretch over a year or more. This project, led by construction tech innovator Luyten, has shattered expectations and demonstrated the incredible efficiency of additive manufacturing. Let’s dive into how this was possible and what it means for the future of building Down Under.

The Project at a Glance

Nestled in a quiet suburb of Melbourne, the structure doesn’t look like a science experiment. It looks like a home. This was a key goal for the project team, a collaboration between Luyten and engineers from Monash University. They wanted to prove that 3D printed homes could be not just fast, but also beautiful, durable, and compliant with Australia’s strict building codes.

The home itself is a modern, three-bedroom, two-bathroom family dwelling spanning approximately 180 square meters. The core structure—the walls—was printed using Luyten’s Platypus X2 robotic printing system. This technology allowed the team to complete the structural elements in a fraction of the time required by traditional brick-and-mortar or timber-frame methods.

Key Statistics of the Build:

- Total Construction Time: just 5 months

- Wall Printing Time: Under 72 hours

- Material Waste Reduction: Approximately 60% less than conventional builds

- Labor Hours Saved: Estimated 70% reduction

From Blueprint to Building in Just 5 Months

The phrase “just 5 months” is the headline figure, but the timeline breakdown is even more impressive. How did the team condense a process that typically takes 12-18 months into such a short window? It all comes down to efficiency and parallel workflows.

Month 1: Digital Design & Site Preparation. While the digital blueprint was being finalized and fed to the printer’s software, the on-site crew prepared the foundation and laid the initial plumbing. There was no waiting for material deliveries or specialized trades to begin. The digital-first approach meant every detail was planned before a single drop of concrete was poured.

Month 2: The Print. This is where the magic happens. The massive robotic arm, guided by the 3D model, began extruding a proprietary, fast-setting concrete mix called ‘Luyten Ultimatecrete 2.0’. Layer by layer, the internal and external walls of the house took shape. The entire structural printing was completed in under three days of continuous operation. The machine even left perfectly measured cavities for windows, doors, and electrical conduits, eliminating the need for later demolition or cutting.

Months 3-5: Finishing. With the core structure complete in record time, roofing contractors, electricians, and plumbers could begin their work almost immediately. This phase, which is often a bottleneck in traditional construction, was streamlined. The roof was installed, windows were fitted, and internal finishing—from drywall to paint—was completed. This ability to run trades concurrently is a huge advantage of the 3D printing method.

The Tech Behind the Speed

At the heart of this project is the 3D printing technology itself, often called Additive Manufacturing. Think of a desktop 3D printer, but scaled up to the size of a building and using concrete instead of plastic.

A robotic gantry system moves a nozzle along a predetermined path, extruding a specially formulated concrete mix. This mix is designed to be fluid enough to be pumped but strong enough to support the subsequent layers almost immediately. This process offers several distinct advantages:

- Speed: As demonstrated, the ability to erect a building’s structure in days, not months, is the primary benefit.

- Reduced Waste: The printer only places material exactly where it’s needed, drastically cutting down on the waste from offcuts and formwork common in traditional building. This is a huge win for sustainable construction.

- Design Freedom: The technology allows for complex and curved walls to be created at no extra cost, opening up new architectural possibilities that would be prohibitively expensive with conventional methods.

- Lower Labor Costs: While skilled technicians are required to operate the printer, the technology reduces the need for large teams of manual laborers for framing and bricklaying.

This isn’t just a concept; companies like COBOD International are deploying these systems globally, proving their viability. Luyten’s success in Australia now firmly places the country on the global map of construction innovation. For more on how our infrastructure is evolving, see our article on The Future of Smart Cities.

A Potential Solution to the Housing Crisis?

The completion of a home in just 5 months is more than a novelty; it’s a direct challenge to the status quo that has contributed to Australia’s housing shortage. With construction costs soaring and skilled labor in short supply, traditional building methods are struggling to keep pace with demand.

Dr. Anya Sharma, a (fictional) urban planning expert at the University of Sydney, commented, “This technology has the potential to be a true disruptor. By significantly reducing build times and labor costs, 3D printing could make new housing stock more affordable and accessible. Imagine being able to build emergency housing after a natural disaster or rapidly develop new social housing projects. The possibilities are immense.”

Of course, challenges remain. Scaling up production, training a workforce to operate the technology, and navigating evolving council regulations will be key hurdles. However, this first successful project serves as a powerful proof-of-concept.

The significant reduction in construction time means a faster return on investment for developers and, hopefully, lower holding costs that can be passed on to the buyer. If the technology can be deployed at scale, it could introduce thousands of new homes to the market far quicker than ever before. To learn more about other innovative solutions, read our post on Affordable Housing Initiatives in Australia.

The journey from a digital file to a finished home in just 5 months is a testament to Australian innovation. It proves that we have the tools and the talent to tackle one of our most pressing national issues head-on. This first house is not just a building; it’s the foundation for a faster, more sustainable, and more affordable future for Australian housing.

“`